CALCINED EGGSHELL – DOPED BIOCHAR AS CATALYST FOR BIODIESEL PRODUCTION FROM WASTE COOKING OIL: A PROCESS OPTIMIZATION STUDY

DOI:

https://doi.org/10.60787/tnamp.v20.384Keywords:

Biodiesel, Calcined eggshell, Optimization, Biochar Heterogeneous catalyst, Response surface methodologyAbstract

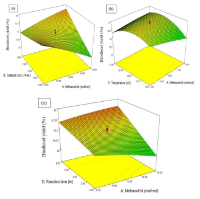

In spite of the numerous advantages associated with use of bio-based heterogeneous catalysts in production of biodiesel, leaching of active sites has remained one of its drawbacks that limits its commercialization. In this study, biochar produced from carbonization of rubber seed shells (RSS) was used as support for synthesis of a low-cost catalyst. The catalyst was synthesized by impregnating the biochar with calcined eggshells. The performance of the catalyst was assessed by conducting transesterification reactions using waste cooking oil (WCO) as feedstock. The transesterification process variables were studied and optimized using response surface methodology (RSM). Results obtained showed that the catalyst was effective in catalyzing the transesterification of WCO. The optimum reaction conditions were: methanol-to-oil molar ratio of 15.8:1, catalyst concentration of 4.0 wt.%, reaction temperature of 61.7 oC, and reaction time of 3.9 h, resulting in biodiesel yield of 93.1 %. Reusability assessment demonstrated catalyst stability to leaching, providing biodiesel yield of 80.1% after the fifth cycle.

Downloads

References

Rahman, W. U., Khan, A. M., Anwer, A. M., Hasan, U., Karmakar, B., & Halder, G. (2022). Parametric optimization of calcined and Zn-doped waste egg-shell catalyzed biodiesel synthesis from Hevea brasiliensis oil. Energy Nexus, 6, https://doi.org/10.1016/j.nexus.2022.100073

Borah, M. J., Das, A., Das, V., Bhuyan, N., & Deka, D. (2019). Transesterification of waste cooking oil for biodiesel production catalyzed by Zn substituted waste eggshell derived CaO nanocatalyst. Fuel, 242,345–354.

Pangestu, T., Kurniawan, Y., Soetaredjo, F. E., Santoso, S. P., Irawaty, W., Yuliana, M., et al. (2019). The synthesis of biodiesel using copper-based metal-organic framework as a catalyst. J Environ Chem Eng, 7.

Jamil, U., Husain, A., Liaquat, R., & Raza, S. (2020). Copper and calcium-based metal organic framework (MOF) catalyst for biodiesel production from waste cooking oil: A process optimization study. Energy Conversion and Management, 215, 112934. https://doi.org/10.1016/j.enconman.2020.112934

Sivamani S, Selvakumar S, Rajendran K, & Muthusamy S. (2019). Artificial neural network genetic algorithm-based optimization of biodiesel production from Simarouba glauca. Biofuels, 10(3):393–401.

Foroutan R, Mohammadi R, Razeghi J, & Ramavandi B. (2021). Biodiesel production from edible oils using algal biochar/CaO/K2CO3 as a heterogeneous and recyclable catalyst. Renew Ener, 168:1207–16.

Olubunmi, B. E., Alade, A., F., Ebhodaghe, S. O. & Oladapo, O. T. (2022). Optimization and kinetic study of biodiesel production from beef tallow using calcium oxide as a heterogeneous and recyclable catalys. Energy Conversion and Management: X, https://doi.org/10.1016/j.ecmx.2022.100221

Etim, A. O., Musonge, P., & Eloka-Eboka, A. C. (2020). Effectiveness of biogenic waste- derived heterogeneous catalysts and feedstock hybridization techniques in biodiesel production. Biofuels, Bioprod. Biorefining 14, 620–649. https://doi.org/10.1002/ BBB.2094.

An, H., Qiu, F., Rude, J. (2021). Volatility spillovers between food and fuel markets: do administrative regulations affect the transmission? Econ. Model 102, 105552. https://doi.org/10.1016/J.ECONMOD.2021.105552.

Amenaghawon, N. A., Obahiagbon, K., Isesele, V., and Usman, F. (2022). Optimized biodiesel production from waste cooking oil using a functionalized bio-based heterogeneous catalyst. Cleaner Engineering and Technology, 8, https://doi.org/10.1016/j.clet.2022.100501

Akhabue, C. E., Osa-Benedict, E. O., Oyedoh, E. A., & Otoikhian, S. K. (2020). Development of a bio-based bifunctional catalyst for simultaneous esterification and transesterification of neem seed oil: Modeling and optimization studies. Renewable Energy, 152, 724–735. https://doi.org/10.1016/j.renene.2020.01.103

Arumugam, A., Thulasidharan, D., Jegadeesan, G. (2018). Process optimization of biodiesel production from Hevea brasiliensis oil using lipase immobilized on spherical silica aerogel, Renew. Energy 116, 755–761.

Sai, B. A. V. S. L., Subramaniapillai, N., Khadhar Mohamed, M. S. B., Narayanan, A. (2020). Optimization of continuous biodiesel production from rubber seed oil (RSO) using calcined eggshells as heterogeneous catalyst. J. Environ. Chem. Eng. 8, 103603 https://doi.org/10.1016/j.jece.2019.103603.

Karmakar, B., Ghosh, B., Samanta, S., Halder, G. (2020). Sulfonated catalytic esterification of Madhuca indica oil using waste Delonix regia : L16 Taguchi optimization and kinetics. Sust. Energy Tech. Assess. 37 100568.

Jamil, F., Sahaya, P., Kumar, M., Al-haj, L., Tay, M., Myint, Z., & Al-muhtaseb, A. H. (2020). Heterogeneous carbon-based catalyst modified by alkaline earth metal oxides for biodiesel production: Parametric and kinetic study. Energy Conversion and Management: X, 100047. https://doi.org/10.1016/j.ecmx.2020.100047

Abdullah, R. F., Rashid, U., Ibrahim, M. L., Hazmi, B., Alharthi, F. A., & Nehdi, I. A. (2021). Bifunctional nano-catalyst produced from palm kernel shell via hydrothermal-assisted carbonization for biodiesel production from waste cooking oil. Renewable and Sustainable Energy Reviews, 137. https://doi.org/10.1016/j.rser.2020.110638

Sahar, Sadaf, S., Iqbal, J., Ullah, I., Bhatti, H.N., Nouren, S., Habib-ur-Rehman, Nisar, J., Iqbal, M. (2018). Biodiesel production from waste cooking oil: an efficient technique to convert waste into biodiesel. Sustain. Cities Soc. 41, 220–226. https://doi.org/ 10.1016/j.scs.2018.05.037.

Amenaghawon, A. N., Odika, P., Aiwekhoe, S. E., (2021). Optimization of nutrient medium composition for the production of lipase from waste cooking oil using response surface methodology and artificial neural networks. Chem. Eng. Commun. 208, 1–11. https://doi.org/10.1080/00986445.2021.1980395.

Osagiede, C. A., and Aisien, F. A. (2024). Biochar-based Bi-functional Catalyst Derived from Rubber Seed Shell and Eggshell for Biodiesel Production from Waste Cooking Oil. Fuel, 358. https://doi.org/10.1016/j.fuel.2023.130076

Osagiede, C. A., and Akhabue, C. E. (2024). Kinetics and thermodynamics studies of the transesterification of waste cooking oil using biochar-based catalyst derived from rubber seed shells. Journal of Science and Technology Research, 6 (2), pp. 319 – 330. https://doi.org/10.5281/zenodo.12706977

Al-Muhtaseb, A. H., Jamil, F., Al-Haj, L., Zar Myint, M. T., Mahmoud, E., Ahmad, M. N. M., Hasan, A. O., & Rafiq, S. (2018). Biodiesel production over a catalyst prepared from biomass-derived waste date pits. Biotechnology Reports, 20. https://doi.org/10.1016/j.btre.2018.e00284

Ahmad, J., Yusup, S., Bokhari, A., and Kamil, R. N. M. (2014). Study of fuel properties of rubber seed oil-based biodiesel, Energy Convers. Manage. 78, pp. 266–275.

Degfie, T. A., Mamo, T. T., Mekonnen, Y. S. (2019). Optimized biodiesel production from waste cooking oil (WCO) using calcium oxide (CaO) nano-catalyst. Sci Rep, 9: 18982. https://doi.org/10.1038/s41598-019-55403-4

Wang, S., Shan, R.., Wang, Y., Lu, L., and Yuan, H. (2018). Synthesis of calcium materials in biochar matrix as a highly stable catalyst for biodiesel production. Renewable Energy, 10.1016/j.renene.2018.06.047.

Al-Sakkari, E. G., El-Sheltawy, S. T., Abadir, M. F., Attia, N. K., and El-Diwani, G. (2017). Investigation of cement kiln dust utilization for catalyzing biodiesel production via response surface methodology. International Journal of Energy Research, 41, pp. 593–603

Downloads

Published

Issue

Section

License

Copyright (c) 2024 The Transactions of the Nigerian Association of Mathematical Physics

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.