NUMERICAL ANALYSIS OF TEMPERATURE DISTRIBUTION AND SOLIDIFICATION THICKNESS OF LIQUID CAST IN THE MOULD OF CONTINUOUS SLAB CASTING

Keywords:

Solidification thickness, Temperature distribution, Copper mould, Liquid castAbstract

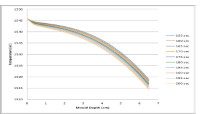

In continuous casting, it is difficult to determine the temperature distribution and solidification thickness using experimental techniques. This paper aim at analysing the temperature distribution and solidification thickness of the liquid cast in the mould numerically with respect to the pouring temperature of 1546 oC and mould preheat temperature of 320oC. The Garlerkin Finite element method was used to discretize and analyse the temperature distribution. The pouring temperature dropped from 1546oC to 1532oC for 50sec, after a time interval of 100sec droped to 1525 oC and further dropped to 1513oC at the outlet of the mould zone. This result corresponds with the results obtained from literature which had a mould outlet temperature of about 1515oC. The thickness was observed to increase after some time to about 2.4375cm which aid the downward movement of the liquid cast into the solidifying steel shell.

Downloads

References

Dhairya S.D. et. al. (2015), “A study of core and its types for casting process”, International Journal of Advanced Technology in Engineering and Science, vol. 3 (1), pp: 1571 – 1580.

Ibhadode A.O.A. (2014): “Introduction to Manufacturing Engineering”. Ambik Press, Benin city, Edo State, Nigeria.

Meng Y. and Brian G. T. (2003): “Heat Transfer and Solidification Model of Continuous Slab Casting: CON1D”. Metallurgical and Materials Transactions B, Vol. 34B, No. 5, pp. 685-705.

Marcial G., Marcela B. G., Andrea P. A., Elena F. B., and Eduardo N. D. (2003): “Modeling of theSolidification Process in a Continuous Casting Installation for Steel Slabs”. Metallurgical and Materials Transactions B, volume 34b, pp. 455- 474.

Choudhary S. K. and Mazumdar D. (1995), “Mathematical modeling of fluid flow, heat transfer and solidification phenomena in continuous casting of steel”, Steel Research, vol. 66, pp: 199-205.

Reddy J. N. (2006): An introduction to the finite element method, Mcgraw-Hill, Third Edition, Texas.

Hadała B., Malinowski Z., Telejko T. (2016), “Analysis of the slab temperature, thermal stresses and fractures computed with the implementation of local and average boundary conditions in the secondary cooling zones”, Archives of Metallurgy and Materials, vol. 61(4), pp: 2027-2035.

Francis-Akilaki T.I., Omoregie M. J. and Erhunmwun I.D., “Numerical analysis of temperature distribution in continuous slab casting mould”, Journal of Engineering for Development, vol. 13(2), pp:57-66.

Pooria N. J. (2013), “Analysis of Different Continuous Casting Practices Through Numerical Modelling” Master Thesis, Division of Applied Process Metallurgy, Department of Materials Science and Engineering, KTH Royal Institute of Technology, SE-100 44 Stockholm, Sweden.

Alizadeh M., Edris H. and Shafyei A. (2006), “Mathematical modeling of heat transfer for steel continuous casting process”, International Journal of ISSI, vol. 3(2), pp: 7-16.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 The Journals of the Nigerian Association of Mathematical Physics

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.